Since laser technology has been introduced into the cutting sheet metal, CO2 lasers dominate the market. However, the share of fiber lasers in the recent sales is increasing. Compared to CO2 lasers, the simplicity of fiber lasers is obvious: the use of fiber lasers machine footprint is small, the laser light source and cooling system volume is also smaller; no laser gas pipeline, do not need to adjust the lens. Fiber optic light sources with a power of 2kw or 3kw require only 50% of the energy consumption of 4kw or 6kW CO2 laser light to achieve the same performance and faster, lower energy consumption and less impact on the environment.

The key to the problem lies in the laser light source. CO2 laser light sources require a lot of energy to excite nitrogen molecules to collide with CO2 molecules (laser gases), causing them to emit photons and eventually form a laser beam that can be cut through the metal. The molecular activity in the resonator also releases heat while releasing the light, which requires a cooling system to cool the laser gas. This means that more energy is consumed in the cooling process, further reducing energy efficiency.

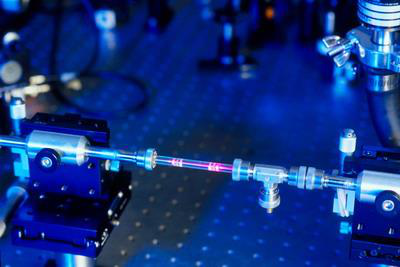

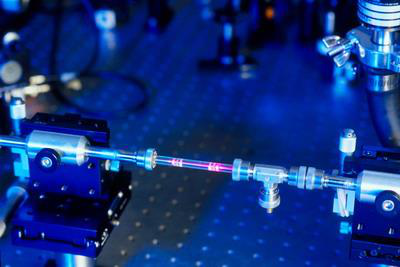

On the other hand, the fiber laser uses a solid-state diode to pump molecules in the double-clad ytterbium-doped fiber, and the stimulated emission light passes through the core a plurality of times, and then forms a laser output through the transmission fiber to the focused head. Since all intermolecular collisions occur within the fiber, laser gas is not required, so the energy required is greatly reduced - about one-third of the CO2 laser. The smaller the amount of heat generated, the volume of the cooler can be reduced accordingly. In summary, the overall energy consumption of fiber lasers is 70% lower than that of CO2 lasers in the same performance.