Laser processing is a new processing technology after mechanical processing, force machining, flame processing and electrical processing. Laser as a very unique light source, also known as "light knife", it can solve the different materials processing, molding, preparation and other manufacturing problems.

As a magical "light knife", it has many characteristics: its spatial characteristics of the energy distribution, according to the needs can be "sharp" can be "blunt", with time characteristics can be continuous or modulated output, according to the absorption coefficient of processed materials, the wavelength covering infrared to ultraviolet. A variety of light parameters with the processing of materials ranging from metal, composite materials, semiconductor materials, ceramics, glass, leather, fabric to man-made fibers, and other new materials.

At present, the laser processing laser more than the infrared band. According to the material to absorb the laser energy generated by the temperature rise, the laser can interact with the material process is divided into the following stages:

1, no heat or basic optical stage.

From the microscopic point of view, the laser is engaged in degenerate photons, when its power density is very low, the vast majority of the incident photons are electron elastic scattering, this main physical process for reflection, transmission and absorption.

2, the following transformation point heating.

When the incident laser intensity increases, the incident photon and metal in the electrons produce inelastic scattering, electrons through the "inverse tough radiation effect", from the photon to obtain energy. The electrons in the excited state interact with the phonons, pass the energy to the phonons, and stimulate the intense lattice vibrations, making the material hot. When the temperature is lower than the phase transition point, the material does not change the results.

3, above the point of change but the melting point of heating.

This stage is the solid state transition of the material, there is heat transfer and mass transfer physical process.

4, above the melting point, but below the vaporization point of heating.

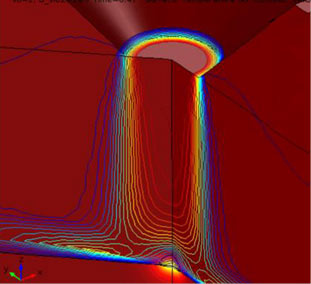

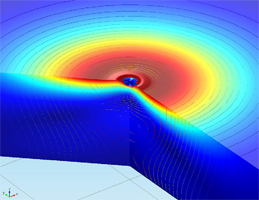

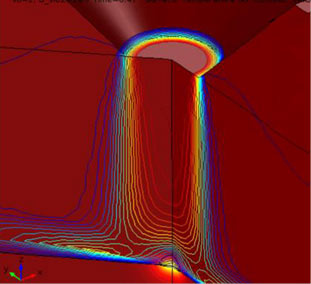

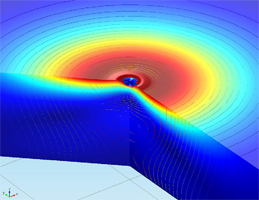

The laser melts the material to form a molten pool. Outside the pool is mainly heat transfer, the pool there are three physical processes: heat transfer, convection and mass transfer.

5, the vaporization point above the heating plasma phenomenon.

The laser vaporizes the material to form a plasma, which is often seen in laser deep welding.

To sum up:

China currently has the laser technology can have a strong ability to produce the laser to the daily life of the laser processing, the advantages of laser technology to provide a broader platform, making products and technologies common development and application, strong the development of laser processing market tomorrow.