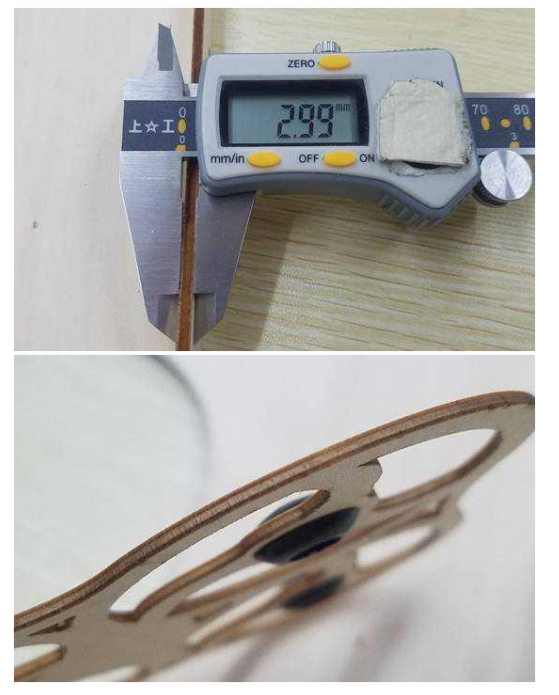

Cutting wood with laser machine have many advantages as following: high precision, little joint-cutting, high speed and smooth surface, but as the focused energy makes the wood burn, so the wood turns black during the cutting, that because the edges of the wood been carbonized. Following we will give the way to avoid this case.

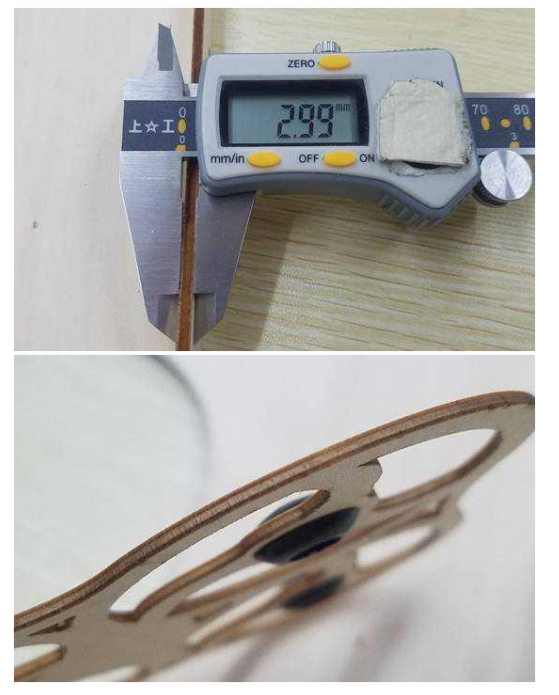

First is how to cut thicker wood board, it is very difficult without burning during the cutting with these board, after our test, we find the way to avoid burning with 5mm wood, following is the way how to operate:

We all know we should use high speed and low power in the cutting to avoid the carbonization, but that is not mean it is better with more and more high speed, lower and lower power, it is not good with more times cutting with such condition. We must insure that the cutting be finished once with low power and high speed, if not the carbonization will be more serious, because the cutting parts should be burned twice, the cutting you make more, the carbonization more serious.

So the first important thing is make sure that the cutting processing should be finished in one time.

In the other ways, the high speed and low power is contradictory, the faster speed, the more difficult to cut through the board, and also the smaller power we use, the difficult for the cutting, so we need to prioritize these two, according to our test, the high speed is more important, following is the data of our test.

Cutting for 3mm glued wood, with power 55%, speed: 45mm/s

Cutting for 5mm polywood, with power 65%, speed: 20mm/s