1. High efficiency

Due to the transmission characteristics of the laser, the laser cutting machine is generally equipped with multiple CNC workstations; the entire cutting process can be processing fully CNC. During the operation, just change the NC program, you can apply different shape cutting parts, both for two-dimensional cutting, but also to achieve three-dimensional cutting.

2. Fast speed

Cutting with the 2 mm thick mild steel plate, use the machine with the power of 1200 W and cutting speed at 600 cm / min; cutting polypropylene resin plate with 5mm thickness at the cutting speed of 1200 cm / min. Materials do not need to be fixed during the laser cutting.

3. Good quality cutting

A: The laser cutting with narrow incision, parallel to both sides of the incision and perpendicular to the surface of the materials, the accuracy of the cutting parts can reach to ± 0.05mm.

B: the cutting surface is smooth and beautiful; the surface roughness only with tens of microns and the laser cutting even can be used as the last process, without any more machining, the spare parts that processing with laser machine can be used directly.

C: the material after laser cutting, the width of heat affected zone is very small, material properties near the kerf is also almost unaffected, and the deformation of workpiece is small, cutting with high precision, cutting geometry shape is good, the cross-sectional shape is more rectangular.

4. Non-contact cutting

Laser cutting head does not have direct contact with the workpiece, there is no tool wear. Processing for different different shapes of parts, do not need to replace the "tool", just change the laser output parameters. Laser cutting processing with low noise, slight vibration and small pollution.

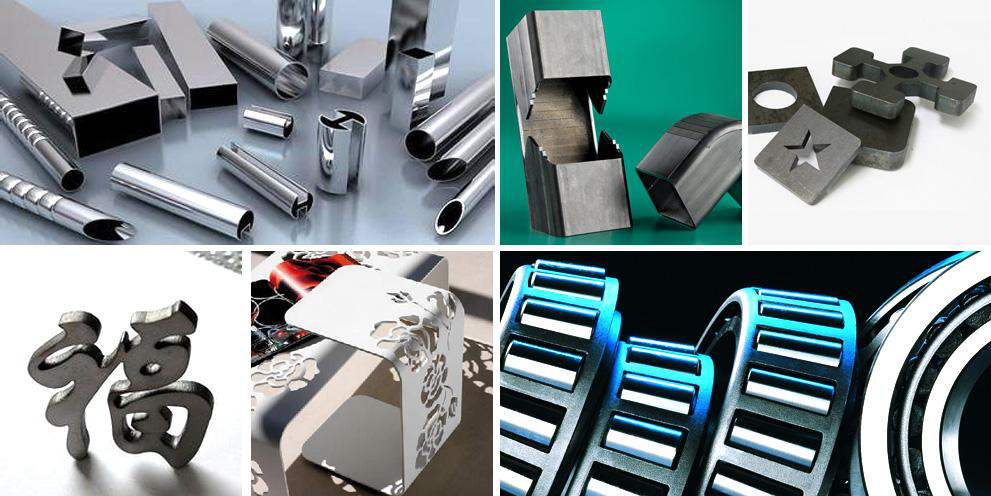

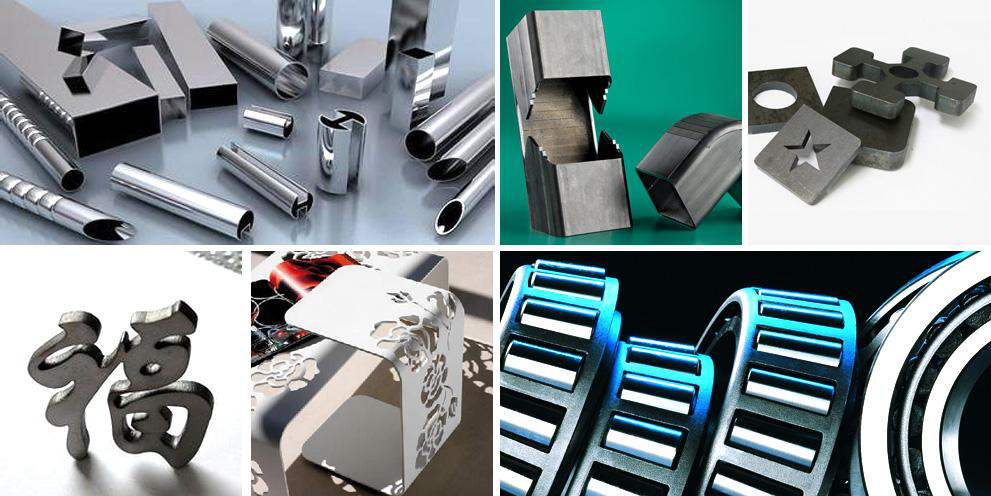

5. Cutting materials is variety

Compared with oxyacetylene cutting and plasma cutting, laser cutting can be used for a wide range of materials, including metal, non-metal materials, metal-based and non-metal matrix composites, leather, wood and fiber.

33